About

Who We Are.

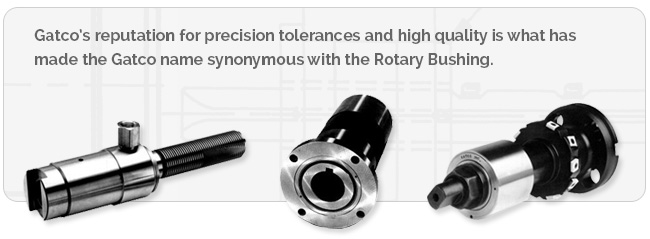

Gatco, Inc. is the originator of the Rotary Bushing. We are a leading supplier to the metal working industry. Gatco products are currently in use all over the world where difficult machining applications are encountered.

Gatco guarantees that all products sold will be within specification and be defect free. If for any reason a customer is not satisfied, simply contact us for an immediate response to your concern.

Gatco Promise

We guarantee that all problems will be resolved to everyone's satisfaction. Gatco values your business and will do everything within our power to keep you has a happy and satisfied customer.

Mission

Since its beginning, Gatco, Inc. has gone to great lengths to provide rotary bushings and toolholders of all shapes and sizes to the metal working industry. We have always felt that satisfied customers are important to us, and lead to repeat business. Consequently, we have never turned down a single request for a special type of rotary bushing or toolholder, no matter how tough the application.

If you have an application which cannot be filled with one of our standard series, don't hesitate to tell us about your problem. Send us a dimensioned sketch of the proposed application, and we will be glad to quote you on a rotary bushing or toolholder to satisfy your needs, at no obligation to you.

Top Quality

Gatco Inc., anti-friction rotary bushings and rotary toolholders are widely used in the metal working industry. When the operation calls for a durable bushing or toolholder which is capable of holding precision tolerances, Gatco is the first to be called. Because of their unique bearing construction Gatco bushings and toolholders operate virtually friction free, which allows for reduced downtime due to frictional wear of the tools. All of our products are manufactured using the latest inspection gages and machinery. Through our comprehensive quality system all parts are monitored for conformance to specification throughout the manufacturing process.

Gatco Inc., anti-friction rotary bushings and rotary toolholders are widely used in the metal working industry. When the operation calls for a durable bushing or toolholder which is capable of holding precision tolerances, Gatco is the first to be called. Because of their unique bearing construction Gatco bushings and toolholders operate virtually friction free, which allows for reduced downtime due to frictional wear of the tools. All of our products are manufactured using the latest inspection gages and machinery. Through our comprehensive quality system all parts are monitored for conformance to specification throughout the manufacturing process.

Gatco Inc., prides itself in the products we manufacture and will continue to strive to provide the metal working industry with the highest quality product available.

Important Note: The recommendations provided here are those generally applicable, but they are not to be interpreted as applying, without reservation or exception, to each and every application. The model and type of each rotary bushing or toolholder selected for a given application, and other conditions surrounding that application, may modify these average limitations one way or the other. Therefore, it is recommended , in most cases, to provide full information to us and let our experienced engineering department submit their recommendation.

Quality Assurance

As designers and manufacturers of precision anti-friction Rotary Bushings and Toolholders, Gatco has attained a leadership position in it’s industry. This has been made possible through the collective talents of the entire work force. Their combined dedication, hard work and expertise produce quality, defect free products. We are proud of our reputation for quality products and will actively promote continuous improvement as a major business objective.

As designers and manufacturers of precision anti-friction Rotary Bushings and Toolholders, Gatco has attained a leadership position in it’s industry. This has been made possible through the collective talents of the entire work force. Their combined dedication, hard work and expertise produce quality, defect free products. We are proud of our reputation for quality products and will actively promote continuous improvement as a major business objective.

Quality Systems

Gatco, Inc. has in place a comprehensive quality system which insures that every product shipped is defect free. We use state of the art machinery and measuring instruments to produce products that meet or exceed specification. We strive for continuous improvement thru training and the implementation of the latest technologies. Every step in the manufacturing process is monitored for quality. Gatco is proud to have achieved Ford’s Q1 award as well as the QE award from Daimler Chrysler. We are currently working to achieve our QS9000 certification. Gatco is commited to quality and will continue to strive to produce the best products in the world.

Components Used

Gatco rotary bushings and toolholders are manufactured using the finest materials available. All approved suppliers must meet stringent quality standards. We use precision bearings of different classes dependent on the accuracy required for a specific application. All parts except bearings and seals are manufactured in our own plant and are monitored throughout the manufacturing process for quality.

Gatco rotary bushings and toolholders are manufactured using the finest materials available. All approved suppliers must meet stringent quality standards. We use precision bearings of different classes dependent on the accuracy required for a specific application. All parts except bearings and seals are manufactured in our own plant and are monitored throughout the manufacturing process for quality.

Special components to meet your requirements are available upon request.

Product Drawings

All of our product drawings are available in ".dwg", ".dwf" , ".dxf", and “.pdf” formats for inserting into AUTO-CAD or other CAD design programs. Just contact us and send us your request. We will email the file back to you immediately.